Vinyl players are machines capable of playing vinyl records. They are sometimes called record players. In this article, I break down the parts of a vinyl player and what to look out for when buying one.

Turntable vs. Record Player

The first major distinction is between a turntable and a record player. There is some debate on whether what you call a vinyl player matters, but in the professional audio industry and among audiophiles, there most certainly is a difference!

What is a Turntable?

A turntable is the essential component that makes a record player. A turntable can play vinyl records, but there are no built-in speakers or other parts. A turntable is made up of the core parts: a platter driven by a motor, a tonearm with cartridge & stylus, a speed selector (33⅓, 45, or 78 RPM), and (in some cases) a pitch shift.

Some turntables come with a built-in phono preamp, which means the RCA output will be line-level or even switchable between line and phono out. However, phono output is the most common. Usually, the receiver, amplifier, or speakers have a phono input which you connect to. If this isn’t the case, you would go through a phono preamp.

What is a record player?

A record player is a turntable with built-in speakers. Over the years, more features have been added to make a record player resemble something closer to a HiFi system. Modern record players may have one or more of the following: CD player, tape cassette, FM radio, AUX, or Bluetooth input. Generally speaking, record players produce poor sound quality.

Modern record players are mass-produced, they’re built cheap, and the sound quality reflects that. Usually, the only reason you’d purchase a record player is due to budget constraints. If you’re serious about your vinyl collection, you want to invest in a quality turntable and some decent speakers.

What Makes a Turntable?

Now that we’ve established what a turntable is, let us briefly dig into each element of a vinyl player so that you know what each part does. This article is intended to understand what you’re buying and what you should be considering when making a final decision.

Belt Drive vs Direct Drive

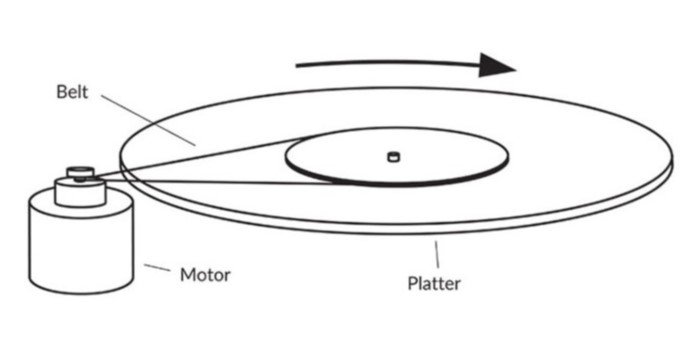

I’ll start with the core of a turntable – the system that makes a turntable platter rotate. Turntable motor systems come in two variations: belt drive and direct drive. While neither system is superior to the other, each is designed to meet specific application requirements.

Belt Drive

A belt drive is the most common drive system in a turntable. The motor and the platter are physically separated from one another. For the platter to turn, it is connected to the motor via a belt. The belt serves two major purposes. Firstly, the belt drives the platter. The second purpose is the belt offers some sound and vibration dampening.

The needle on a turntable is highly sensitive to vibration. As it tracks a vinyl record, the needle reads every bump and groove to produce an electrical signal. Because the needle is so sensitive, any vibrations or noise can be picked up. This is why installing your turntable or record player on a solid surface is best practice. Even the movements of a wooden floor can affect a turntable needle.

Considering this sensitivity, if you had to connect a turntable motor directly to the platter, the noise and vibration from the motor would be picked up by the needle. By separating the motor and needle, the belt acts as a dampener for any noise from the motor.

Belt drive systems are simple and, therefore, the most cost-effective turntable drive system. This is why most turntables on the market are belt-driven. Even many high-end turntables are belt-driven, allowing the manufacturer to focus their budget on other parts to improve sound quality. One thing to note is -when you start a belt drive turntable, there will be some lag before the audio plays at the selected speed. This is because the belt must take up some slack. If you stop the platter with your hand and let it go again, you can clearly hear the belt taking up the tension to play at the correct speed again.

Direct Drive

As the name suggests, the motor on a direct drive turntable connects directly to the platter with no separation. The motor is usually connected right below the center spindle of the platter. Direct-drive turntables require more noise-dampening and vibration-canceling components because no belt can act as a dampener. These components add to the cost of the turntable. Hence, direct drive systems are more expensive.

So, why would you choose a direct drive system if there is no direct effect on sound quality? Direct-drive turntables are preferred by a specific market – DJ’ing. DJs and turntablists require immediate torque and response from a turntable. If a DJ slows down, speeds up, or even scratches a vinyl record, it needs to start again immediately when they release the record.

The BPM (beats per minute) needs to stay constant. If you’re dancing and the BPM isn’t constant, or there is a lag in the record every couple of minutes, the music will sound off, and you will struggle to dance to the music without disruption. DJs also want to make changes that sound musical. If a DJ scratches and then lets the record go, they want the music to continue to sound like it was part of the music. You won’t have this musical effect if the belt must take up the tension every time.

For the consumer market, direct-drive turntables mean a more stable turntable with less wear and tear. If, for example, you live in an apartment with wooden floors that move slightly when you walk, then these movements can affect a belt drive system.

This is when a direct drive system is better suited. Direct drive systems also require less home maintenance, whereas the belts on belt drive turntables experience wear and tear and will need to be replaced at some point. For some, it’s as simple as removing and replacing the belt with a new one.

Some belt drive units, however, require some dismantling to get to the belt. This can be a complicated and finicky procedure. With that being said, though, modern belt drive systems have found an effective way of placing the belt on the outside of the turntable, which means changing the belt can be done in less than a minute.

Tonearm & Cartridge

Now that the platter is turning, the vinyl player needs to read what’s recorded on the vinyl. Inside the grooves of a record are bumps and ridges -these bumps and ridges are what the needle/stylus reads and converts into an electrical audio signal.

Cartridge

The stylus (often called a needle) is made of gemstone – most commonly a small diamond. The stylus is fitted to the end of the cartridge at the tip of the turntable’s tonearm. The stylus directly interacts with the vinyl, tracking the bumps and ridges. The information the stylus reads is then sent to the cartridge.

The cartridge has various components, including a magnet, cantilever, and coil. Movement from the stylus’ tracking is picked up by the cartridge, which, using the various components, converts the movement into an electrical audio signal. The tonearm feeds the electrical signal via four wires through the stereo RCA outputs and then to your HiFi/speakers. In most cases, this signal is an analog phono signal, but some turntables have built-in phono preamps to convert the signal to line level (which we’ll still get later).

Tonearm

The tonearm is an important feature for the stylus to track the vinyl record efficiently. While the stylus tracks the vinyl, the bumps and ridges cause the stylus to move up and down. Without the tonearm, the stylus would bounce around uncontrollably. Essentially, the tonearm acts like a suspension system for the stylus.

The tonearm is unbalanced on cheaper turntables, so a fixed amount of pressure is applied to the vinyl through the stylus. This can cause many issues with effective stylus tracking, ultimately damaging your records. It’s important for a tonearm to be balanced correctly.

If too little pressure exists, the stylus will skip over the bumps and ridges. Subtle movements will result in poor tracking and sound loss. Oftentimes, your vinyl will sound thin with little or no bass. A more exaggerated movement will result in the stylus jumping out of the vinyl groove. This often leads to scratching and damaging the vinyl record.

If the tonearm is too heavy, the pressure will cause the stylus to dig into the vinyl grooves. While the audio playback will sound full and detailed, the recording will wear much quicker. In extreme cases, the stylus might gouge parts of the record – stripping away vinyl. Each turntable is different, and a reputable manufacturer will detail the recommended tonearm weight in the owner’s manual. The pressure can be measured using a pressure gauge.

The tonearm height, design, weight, and cartridge weight need to be considered when deciding on the correct amount of pressure required. The thickness of the record also needs to be considered.

Phono Preamp & Audio Output

The output is the final component of a turntable. This is where the audio signal leaves the turntable to either your HiFi or speakers.

Turntables produce an electrical analog phono signal. For speakers to read this signal, it must be converted to line level. A phono preamp is required to convert the phono signal. Phono preamps are found in one of three places: inside the turntable, a standalone unit, or inside the HiFi receiver or speaker input.

If the phono preamp is inside the turntable, then the RCA output is line level. You can connect directly to your HiFi or speaker line input. This is convenient as most modern electronics don’t have a phono input. Sometimes, the RCA output is switchable, so you can choose whether you want a line level or phono output from your turntable.

Some specialized HiFi and speakers have a built-in phono preamp. The input on these devices will be marked ‘phono’ or ‘phono input.’ Only a turntable or phono signal can be plugged into this input.

Lastly, the phono signal can be converted using an external phono preamp. A phono preamp is a simple device with phono input and line-level output. Any device (a HiFi, speakers, or phono preamp) with a phono input will also have a ground/earth terminal. As a phono signal cable doesn’t have a ground or earth wire, the signal is susceptible to “earth hum.”

This is a constant, low-frequency noise introduced due to insufficient earth shielding. A wire is connected from the turntable to the device you are plugging into to eliminate the earth hum. This wire is usually fixed to the turntable with an exposed end to connect to the earth terminal on the device you’re connecting your RCA cable to.

Conclusion

I hope this article has given you more insight into the inner workings of a vinyl player. A turntable is an analog system, which means, for the most part, it is a relatively simple device to understand.

One thing to remember regarding an analog device like a turntable is that cheap parts are revealing. Unlike digital electronics with intricate circuits and algorithms, a turntable involves many moving parts. Cheap moving parts require more replacing and servicing. In some cases, the parts are so cheap it costs less to purchase a new turntable or record player than to pay someone to fix it. For this reason, you want to purchase a turntable or record player from a reputable brand with some warranty/guarantee and good after-sales service.